Laser Surface Treatment

Precision Laser Surface Treatment solutions for diverse

Industrial Applications.

Our team can help you find the

right solution for your laser surface treatment application.

Contact us.

Contact us.

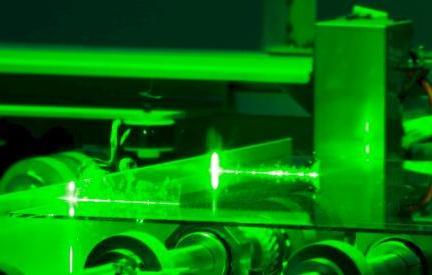

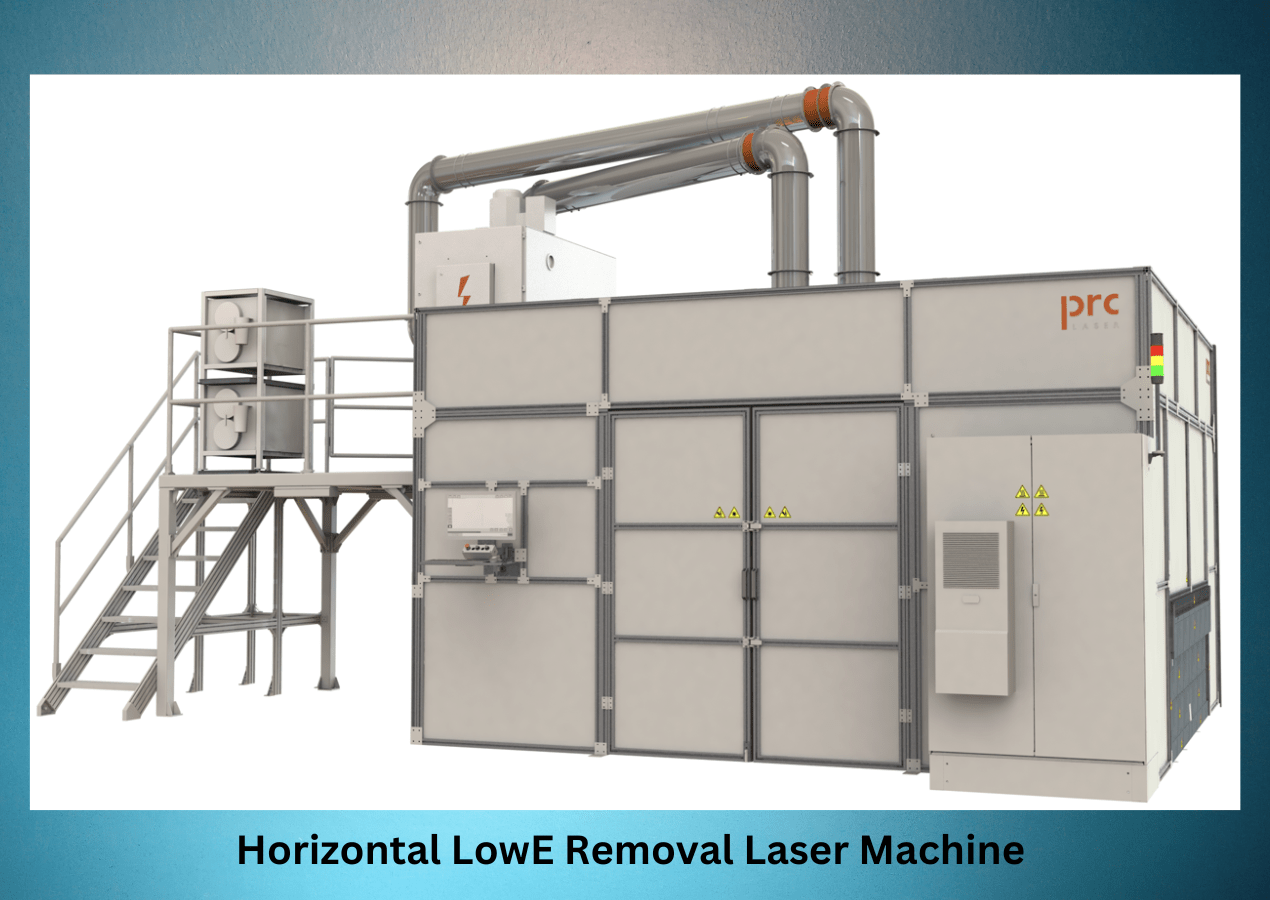

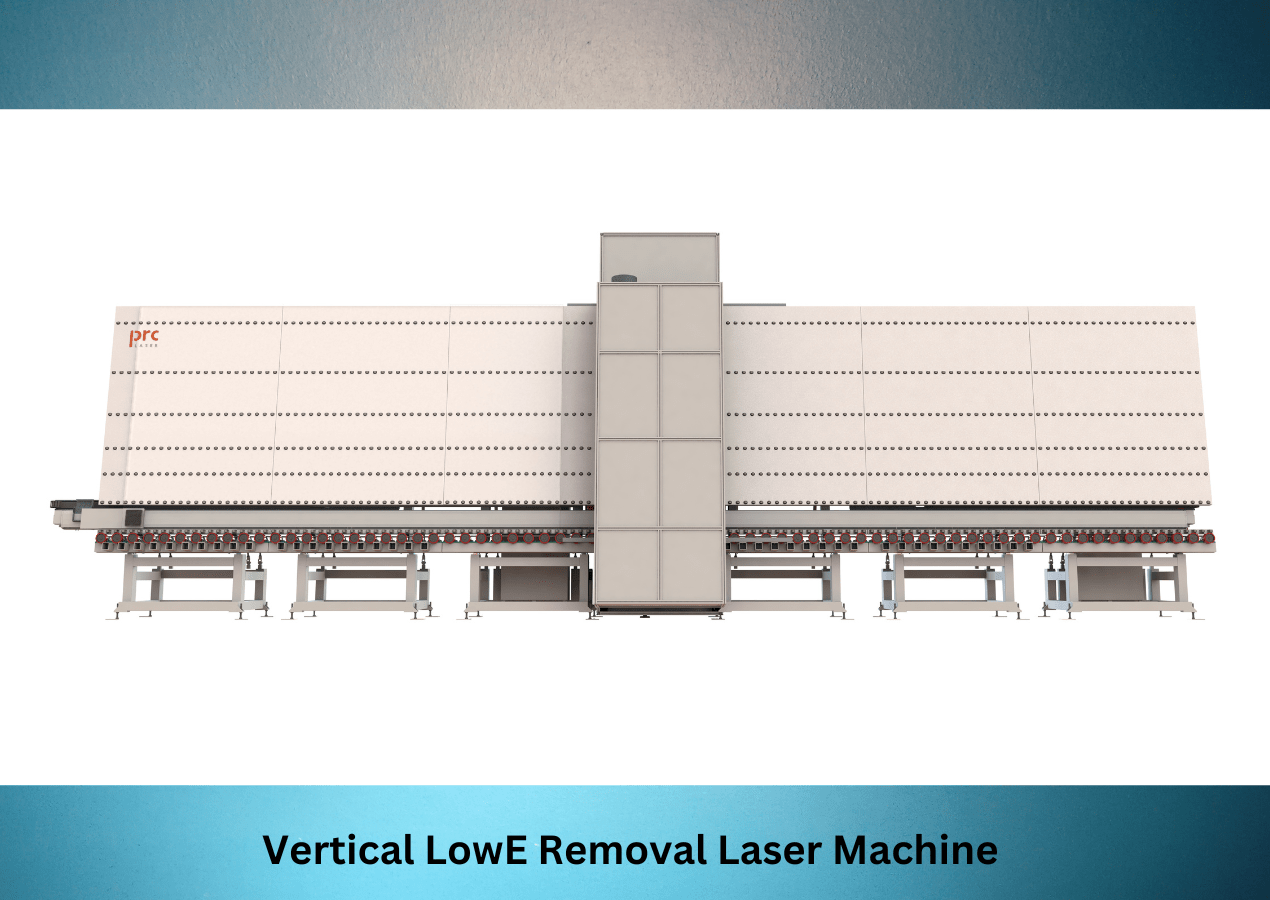

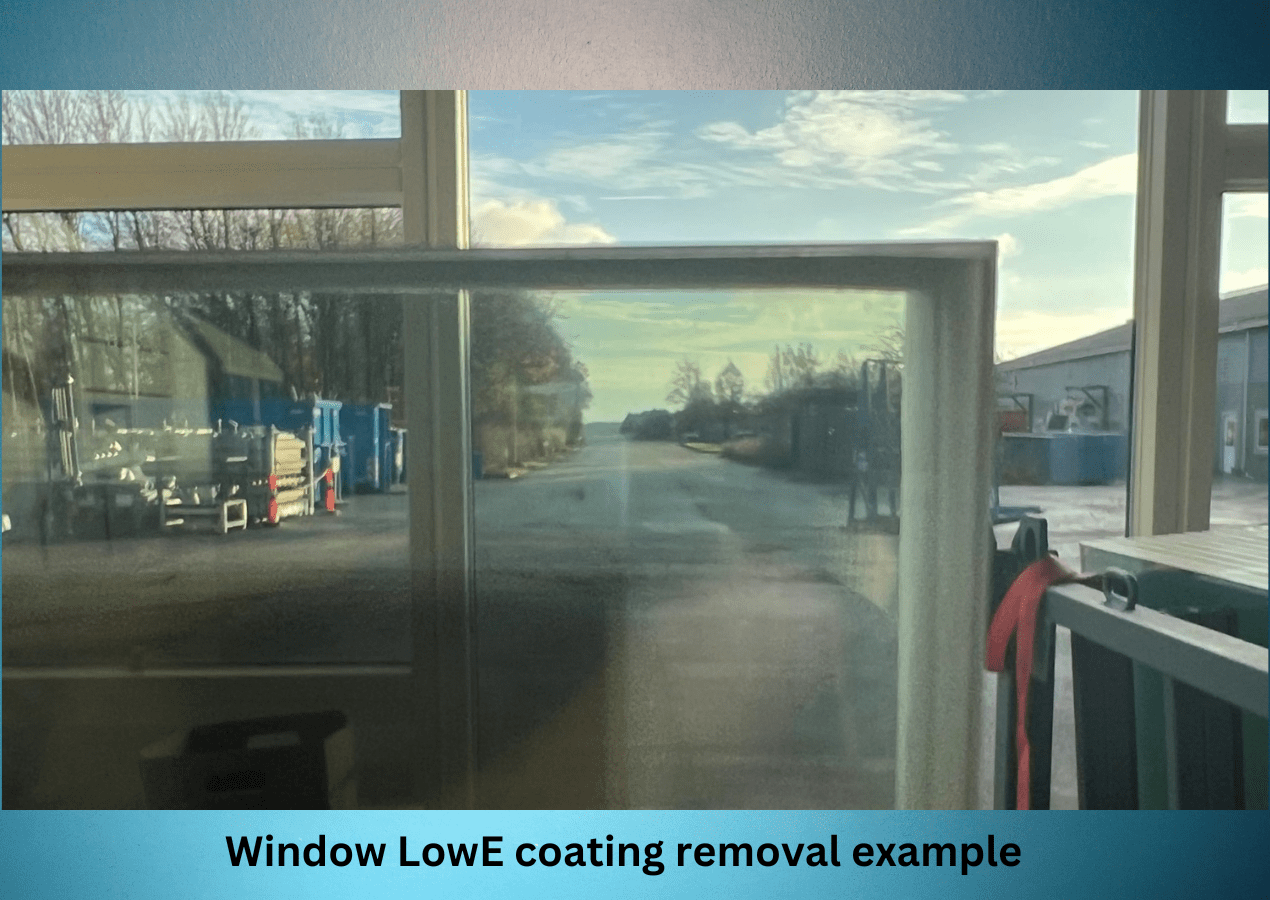

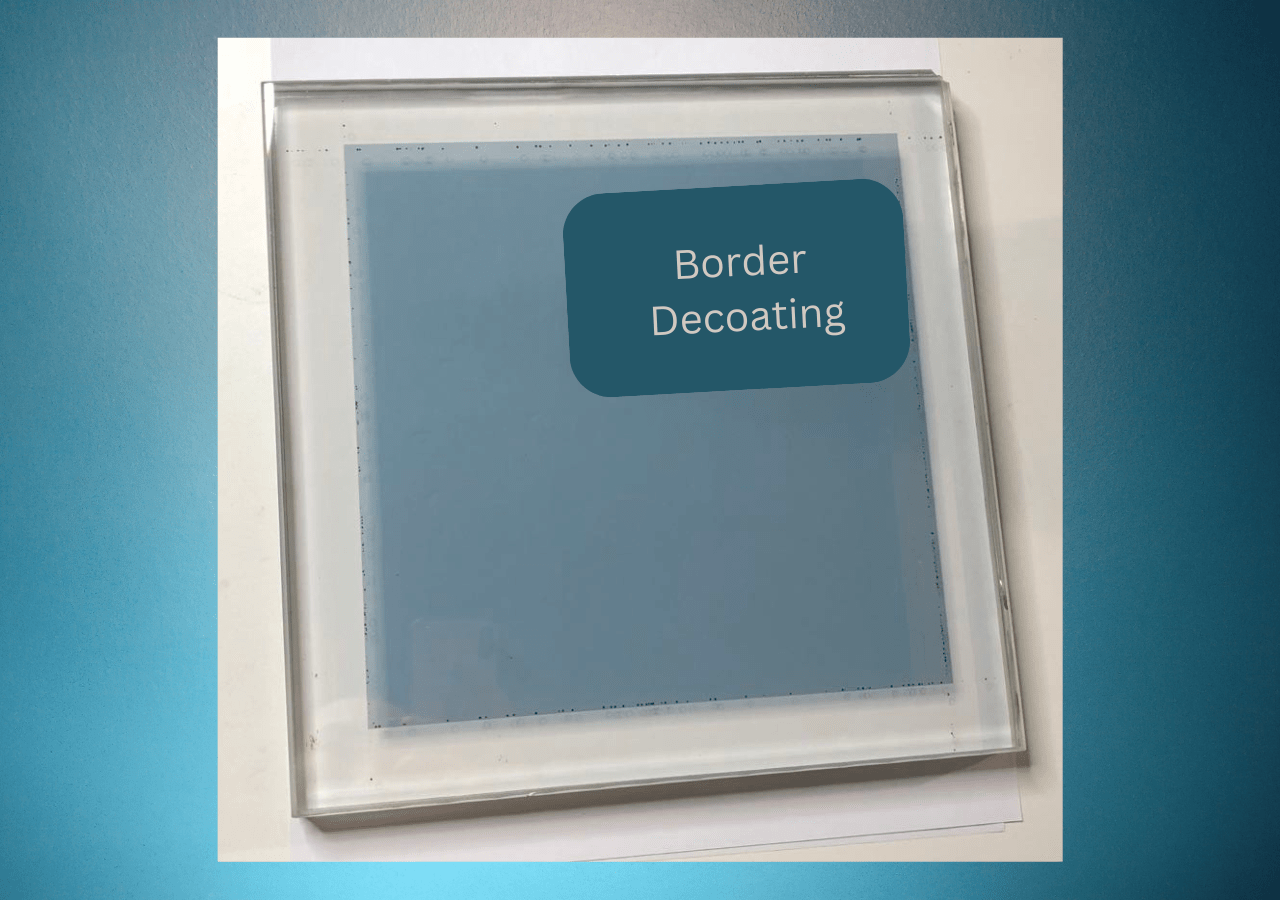

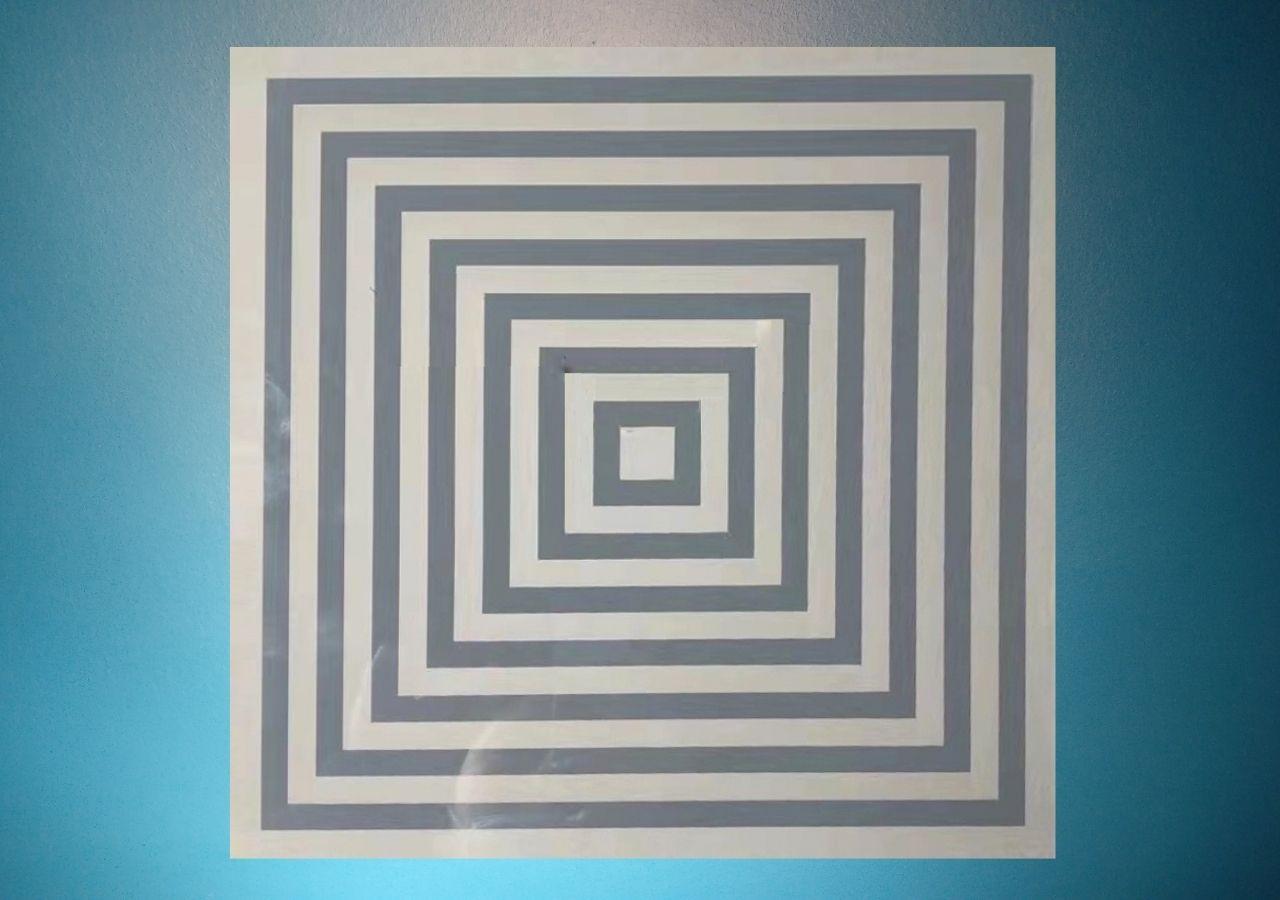

LowE Glass Coating Removal

- Our ultra-fast pulsed laser technology removes LowE & other coatings from glass windows.

- Contactless laser ablation process. A cold process that does not heat or harm the glass.

- Leaves no scratches on glass (No risk of breakage).

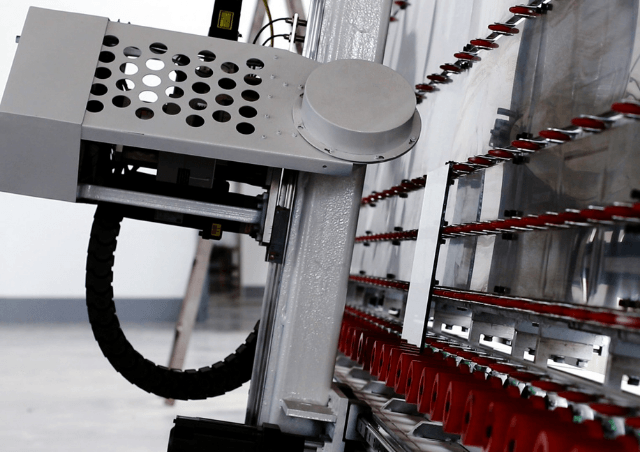

- A High-speed scanner on a CNC controlled gantry removes coatings of different widths along any path or shape.

- 100% coating removal & Zero set-up time!

- Same process can be used on other materials too, such as mirror substrates, metal sheets, etc...

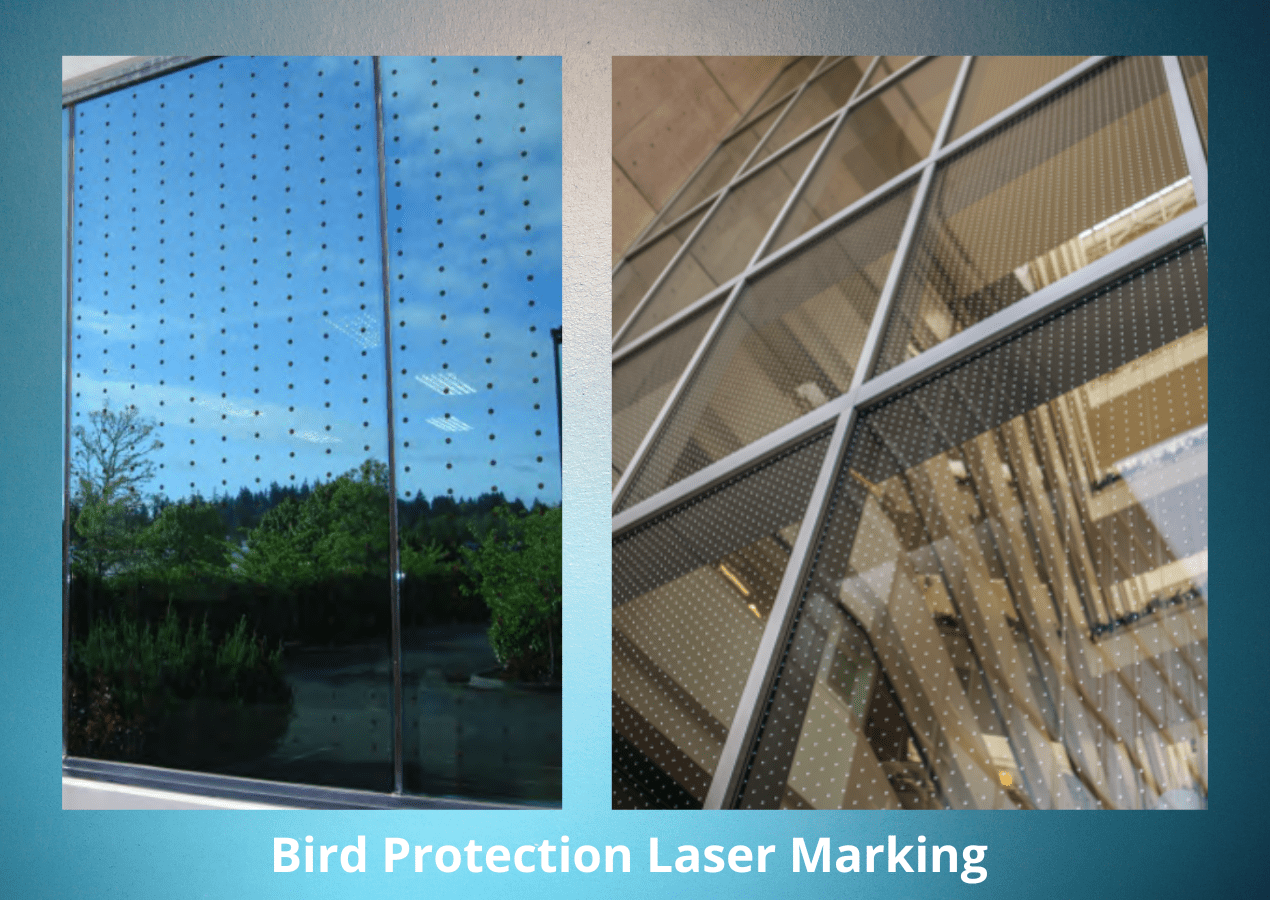

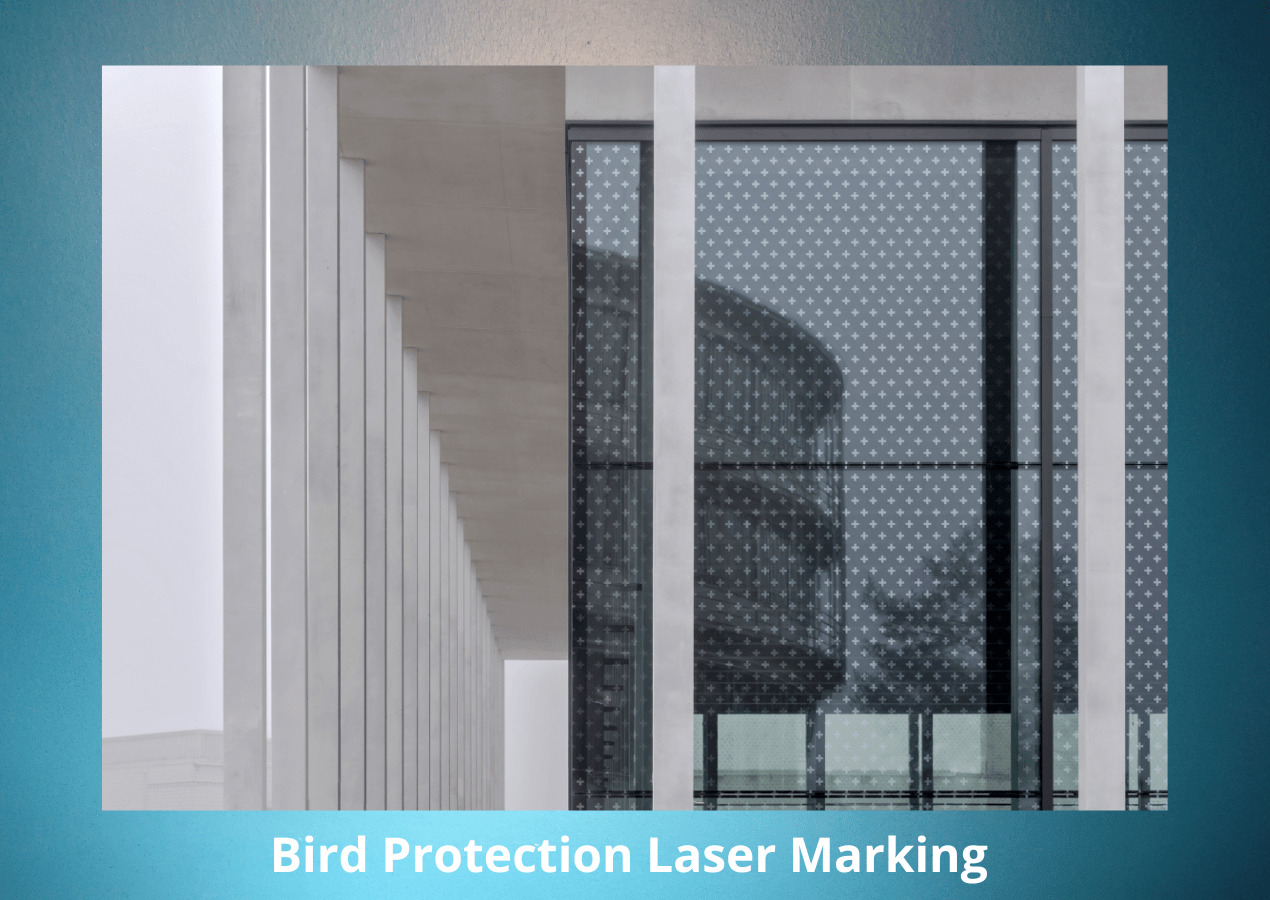

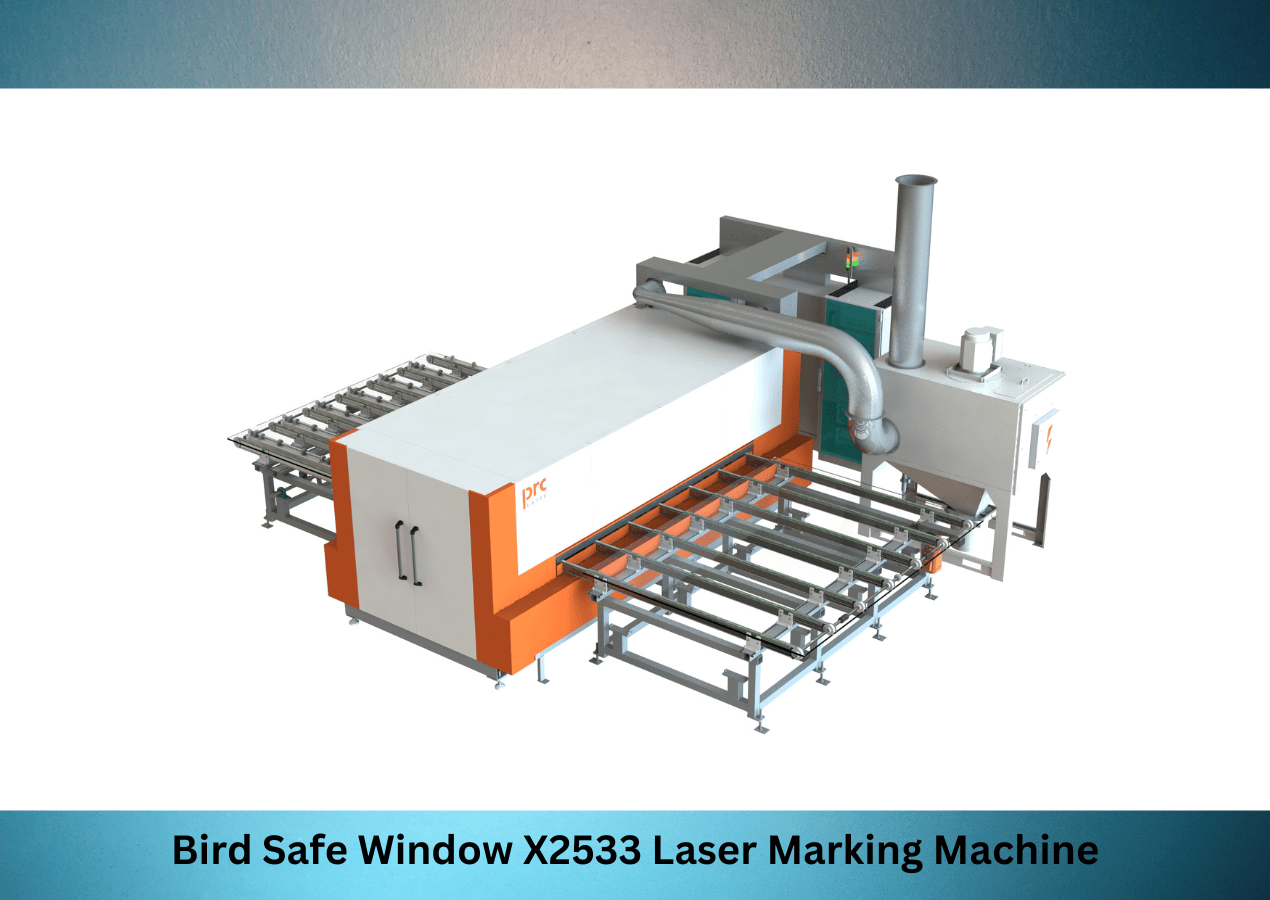

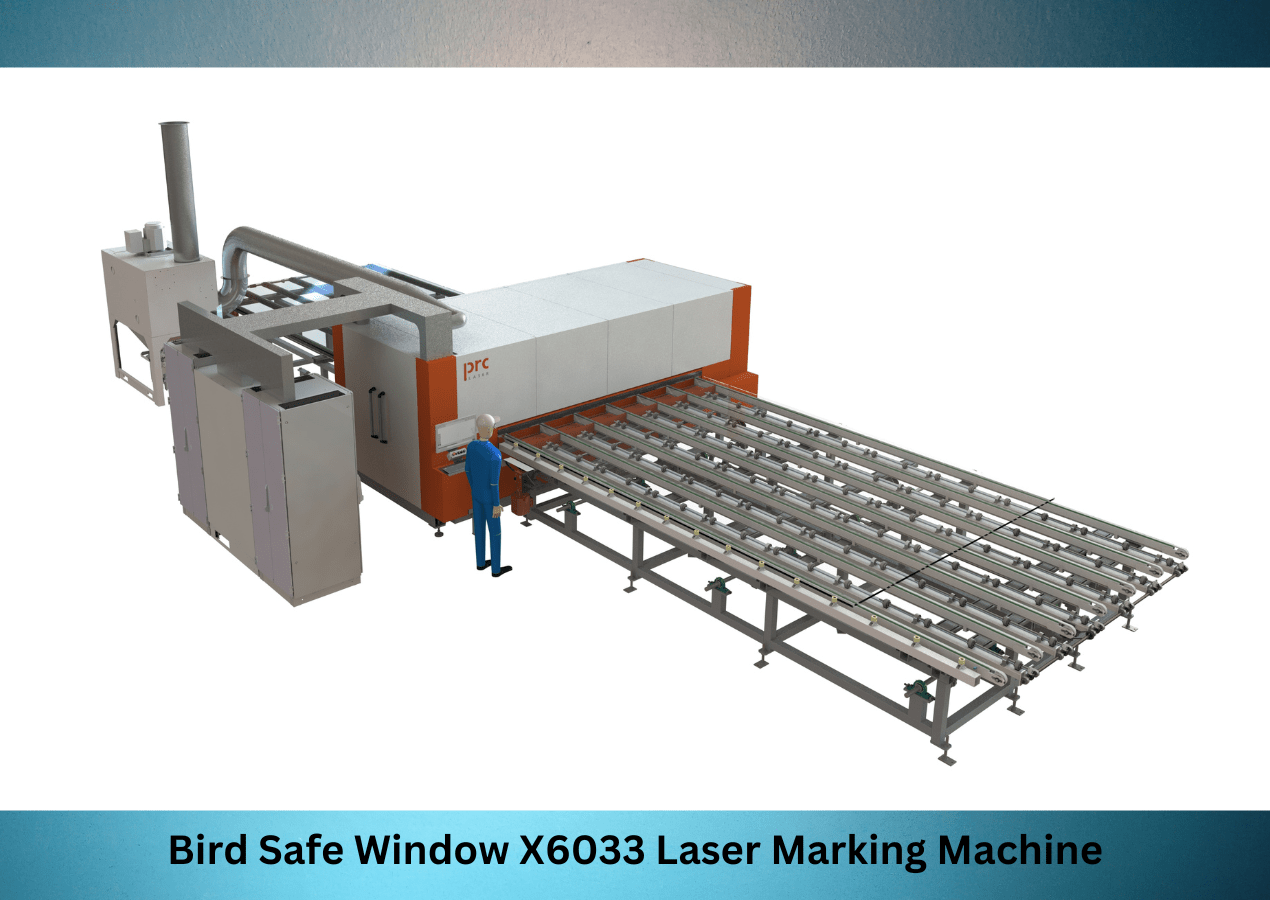

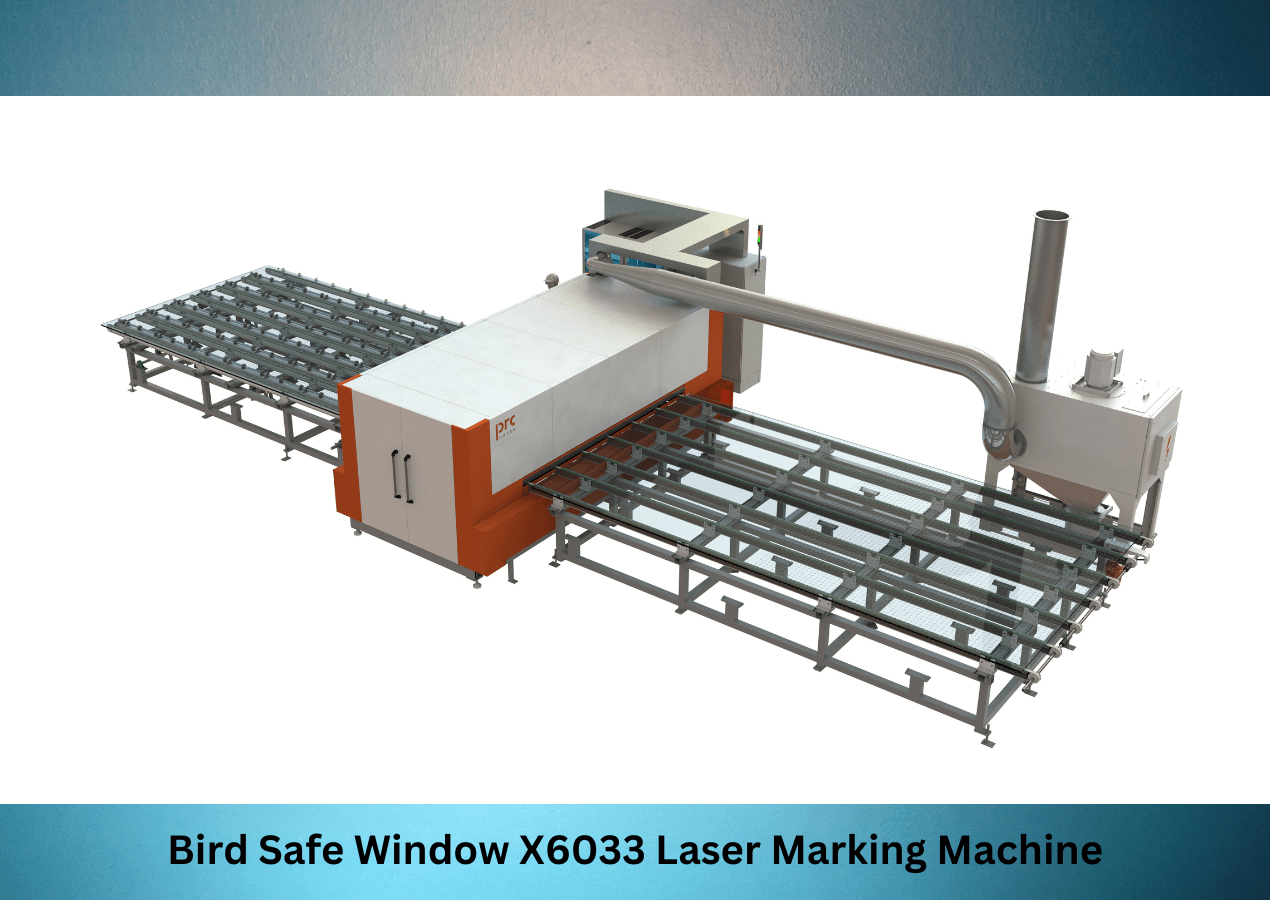

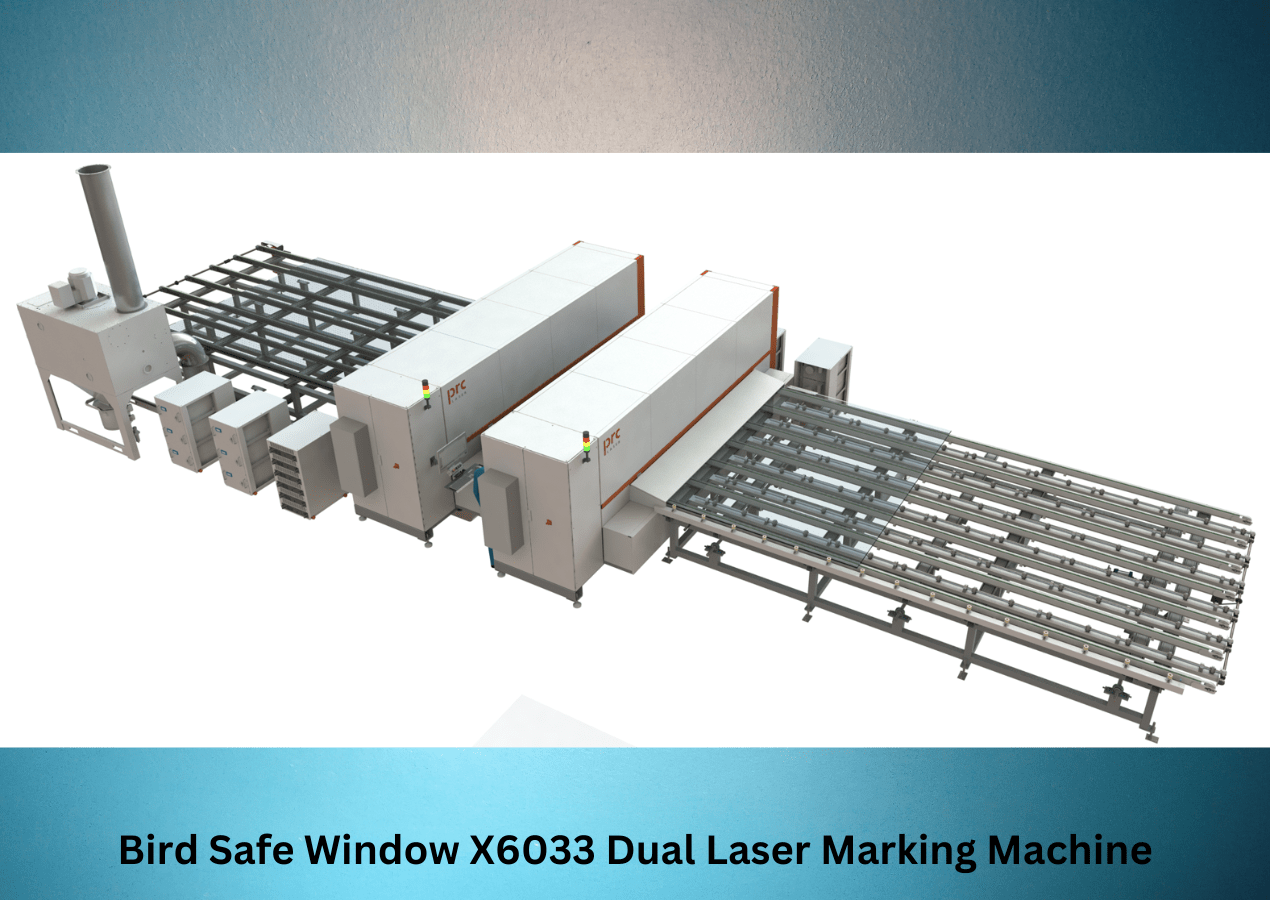

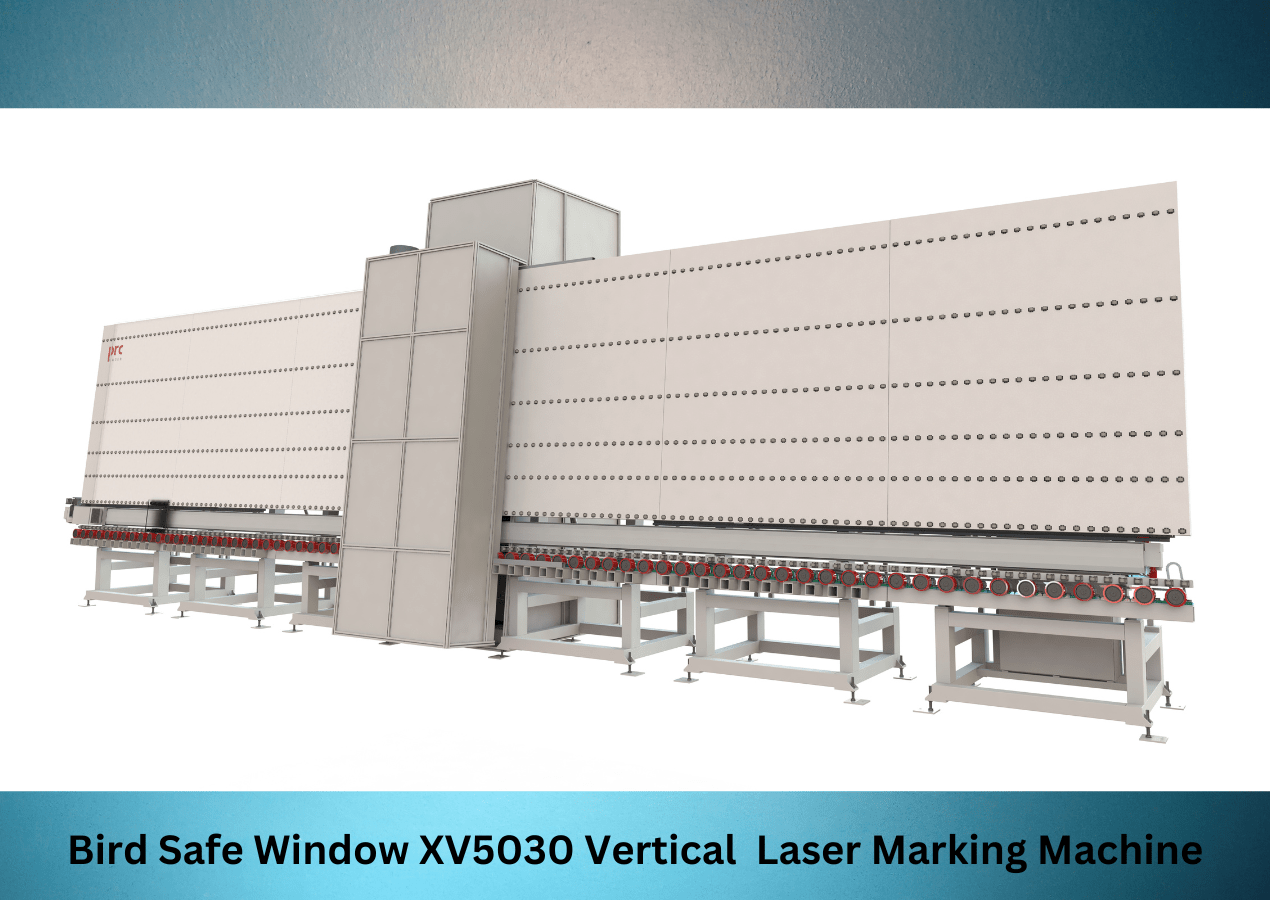

Bird Protection Glass Marking

- Bird "Friendly" windows are windows with a visual barrier allowing birds to distinguish windows.

- The visual barrier can be marked with a laser system in a very economic and flexible way.

- Glass Surface OR Sub-surface marking.

- Any Shape or Pattern possible! Easy setup!

- Contrast and transparency of the marked features can be easily adjusted by laser parameters.

- Environmentally friendly (no chemicals, no waste products).

- Laser marking is permanent and does not wear!!

- Contactless process (no risk of breakage).

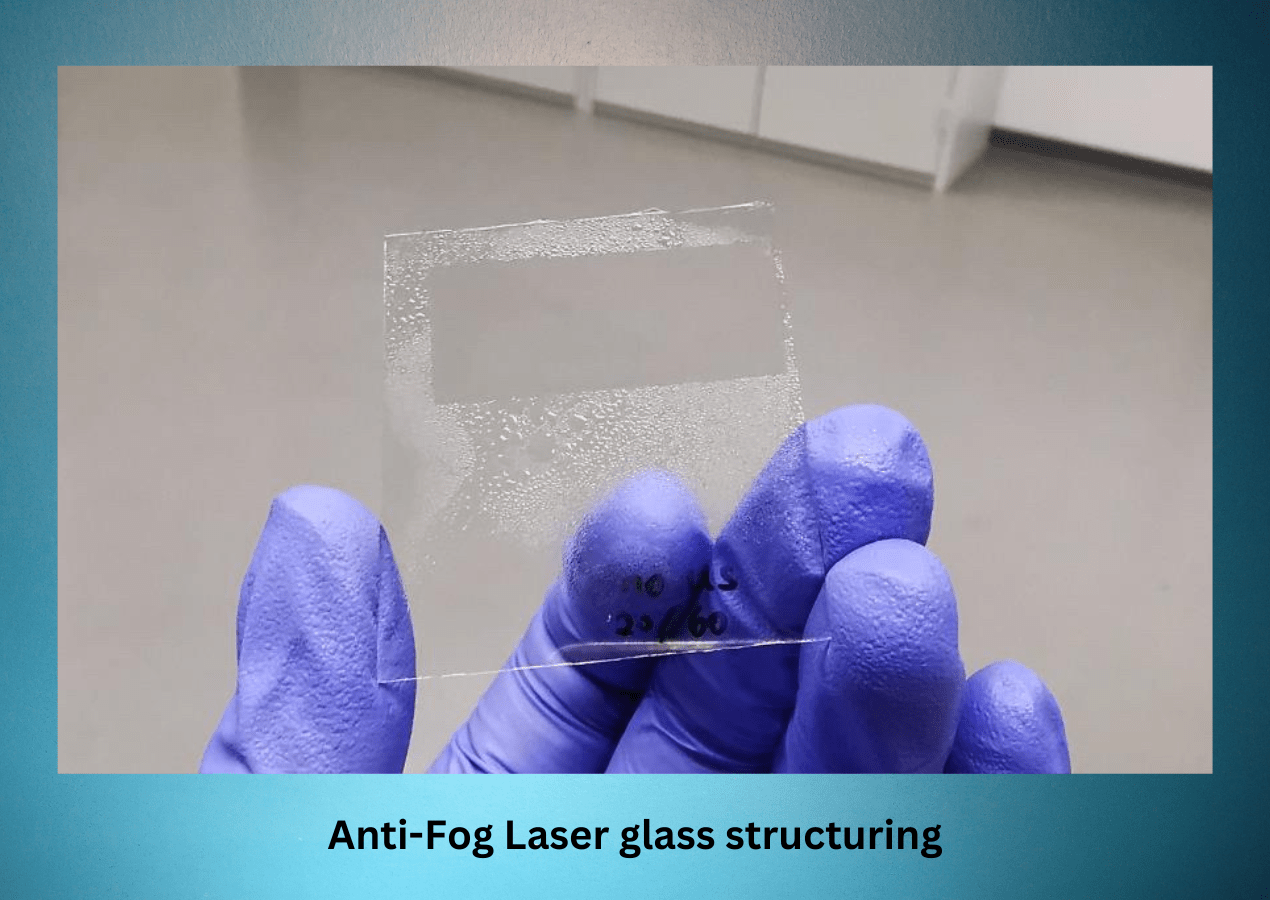

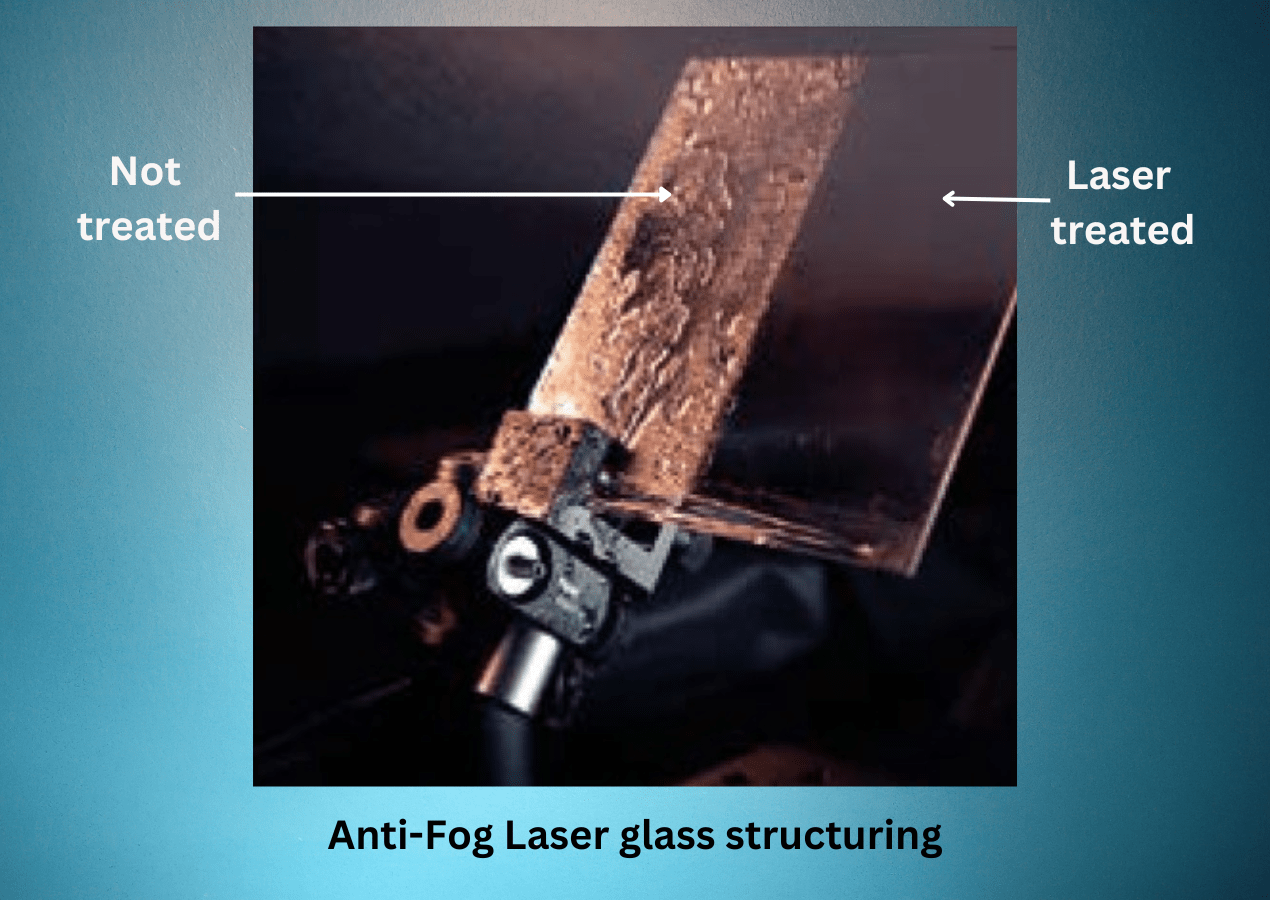

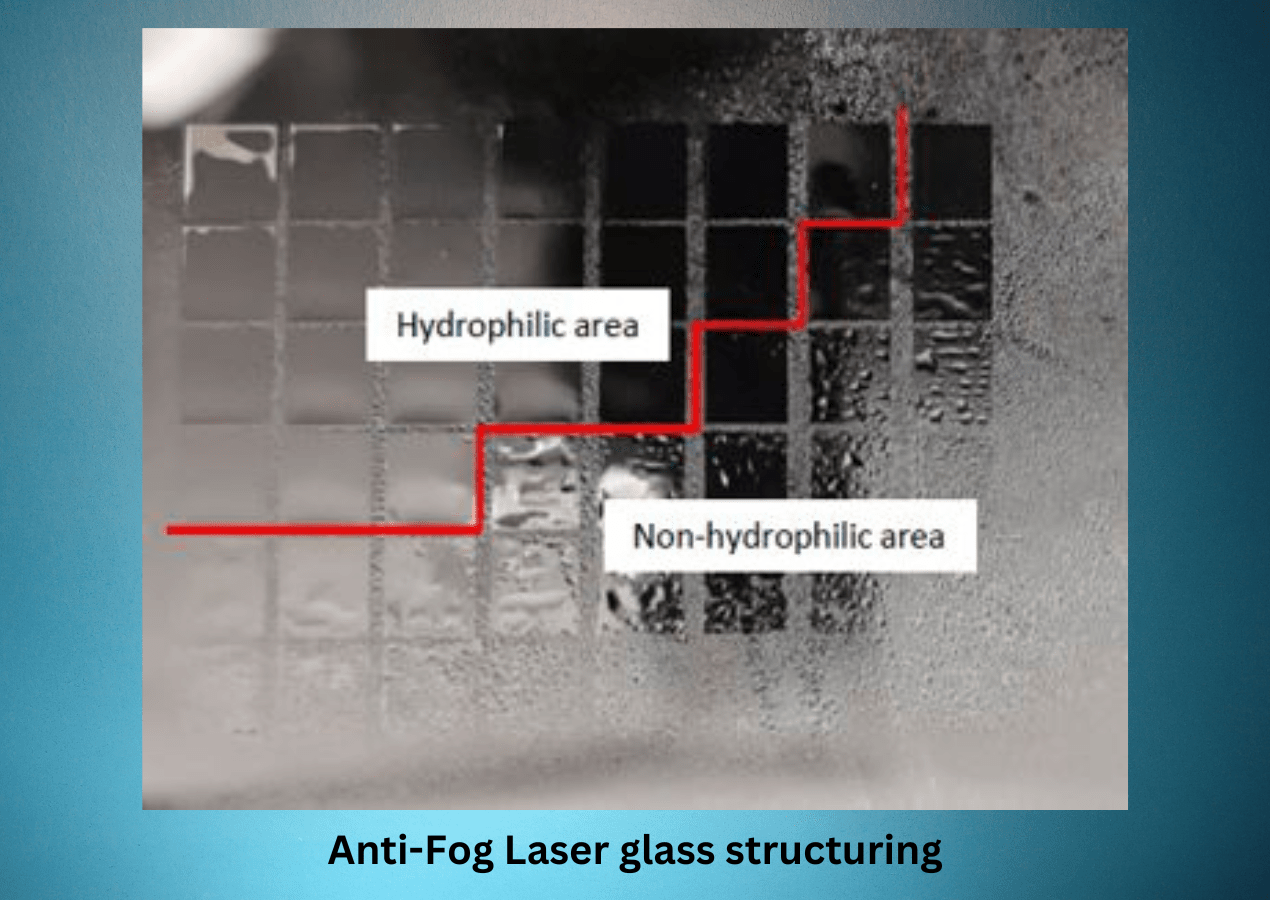

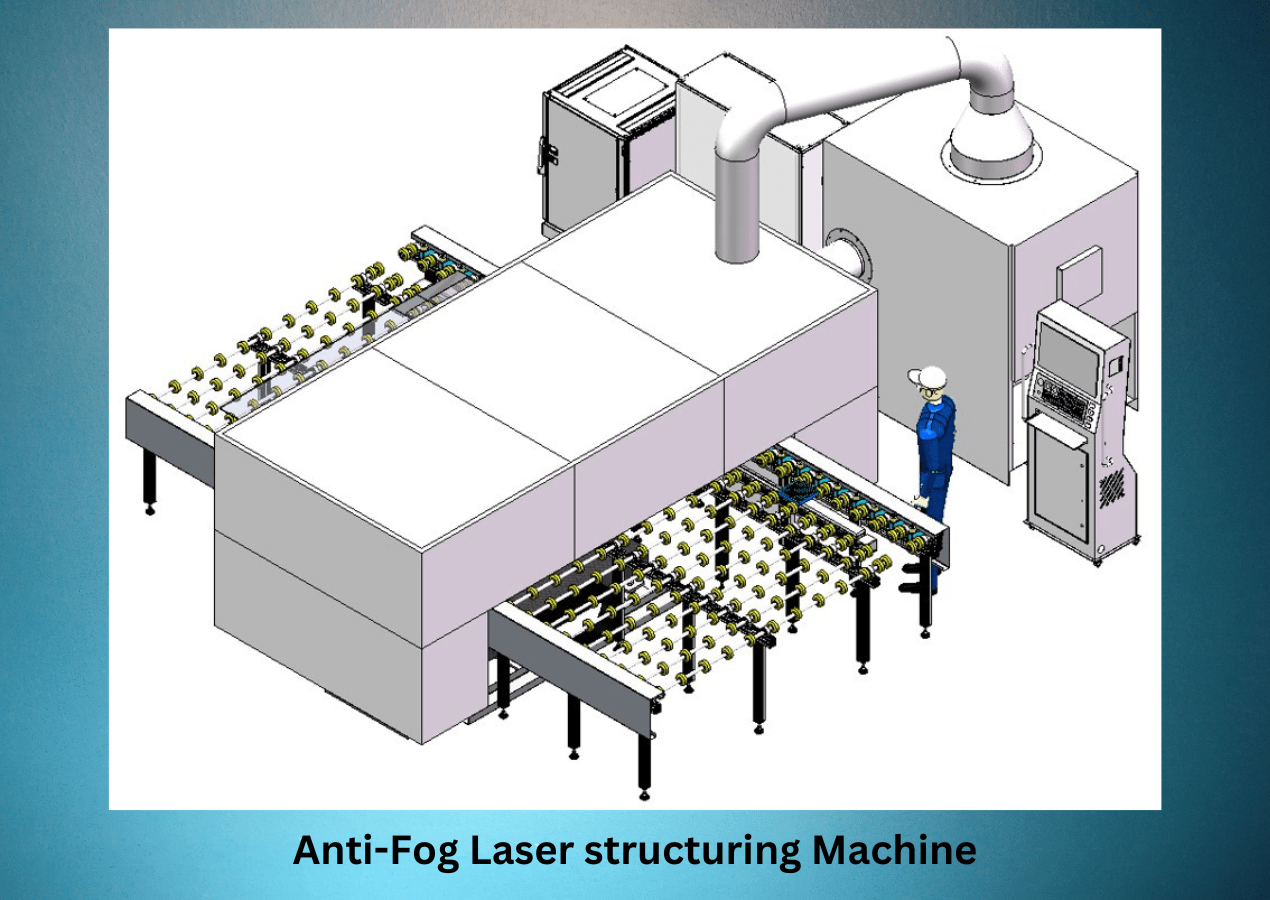

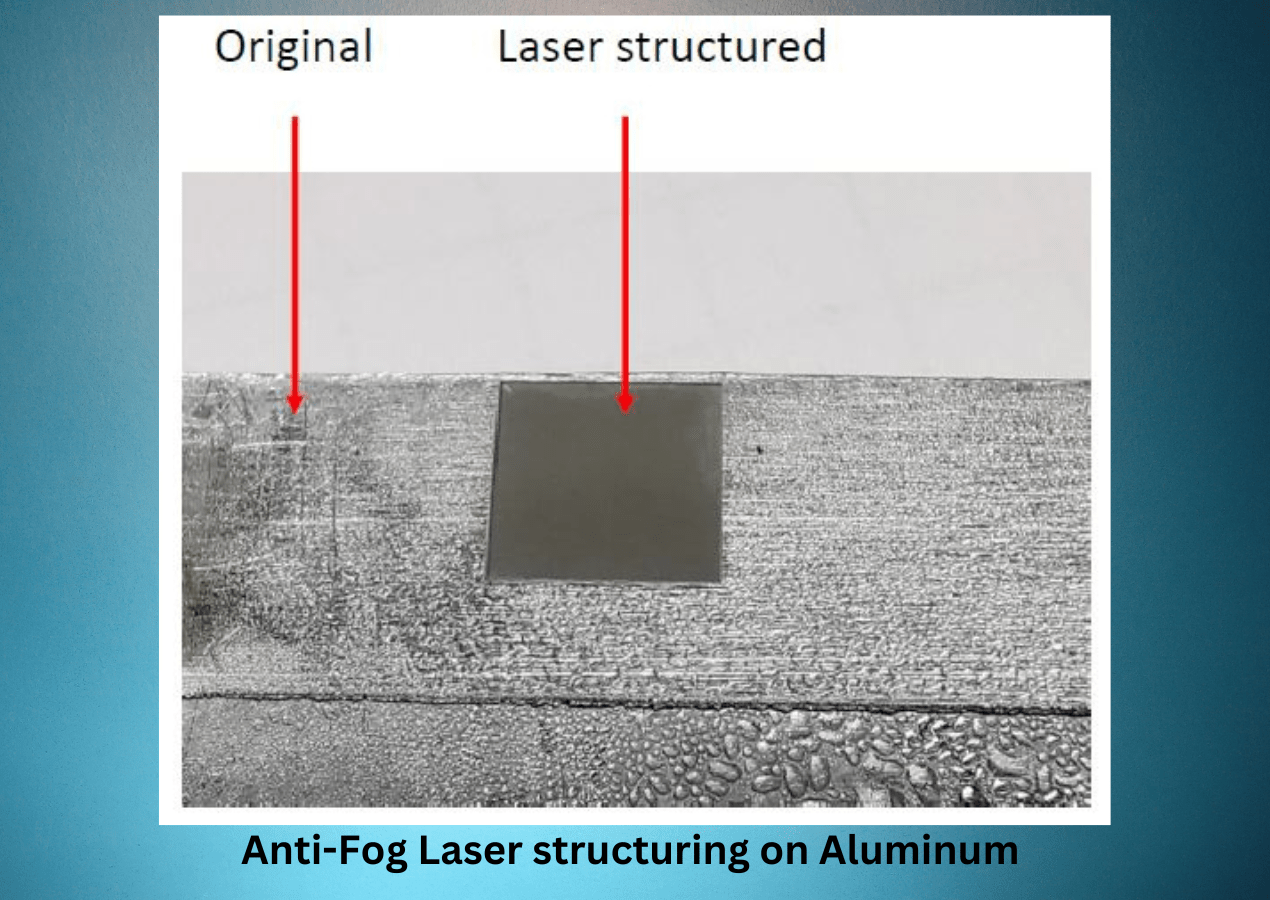

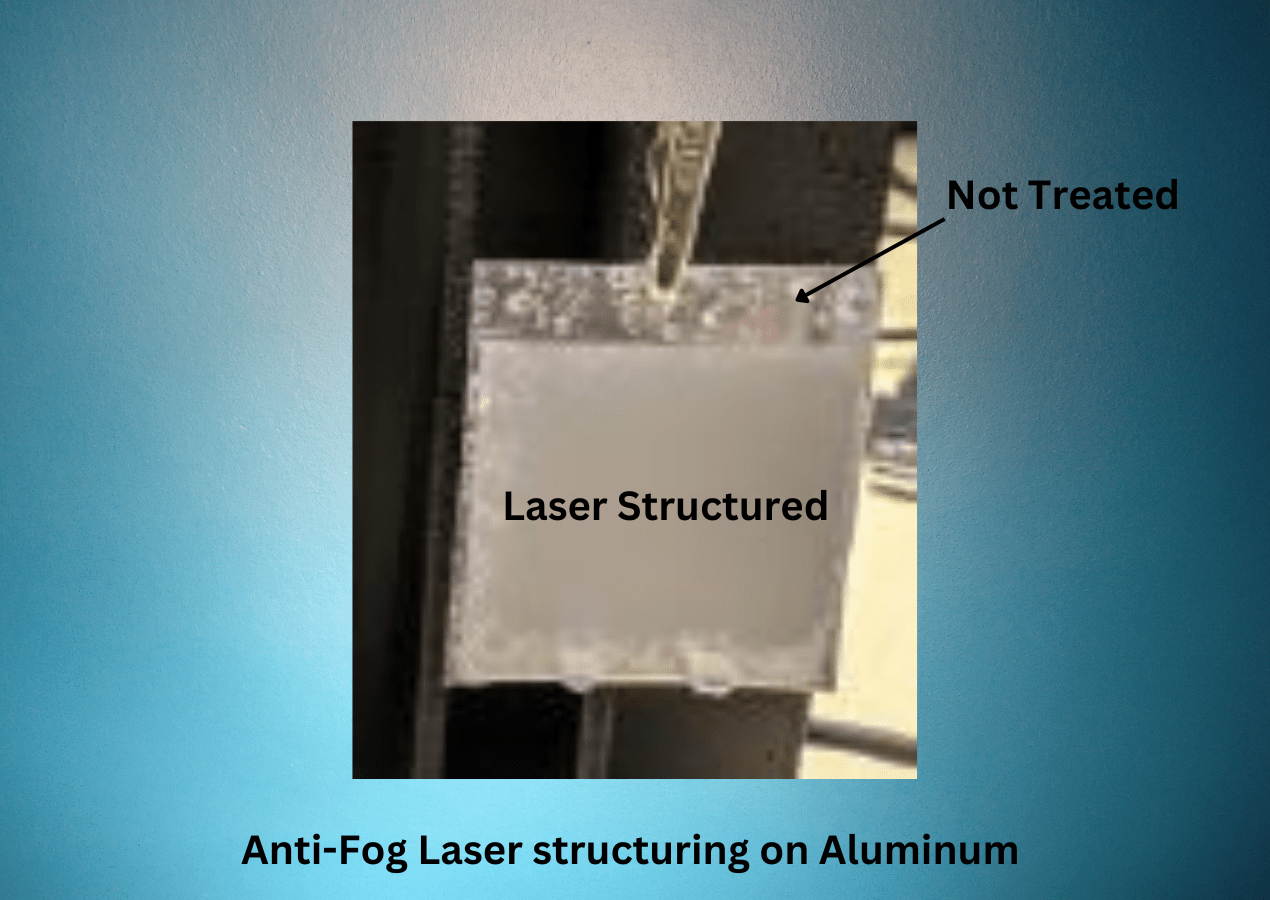

Anti-Fog Laser Structuring

- Anti-Fog Laser Structuring on glass windows changes the glass surface into an hydrophilic, water repellent surface.

- Anti-Fog Glass Surface structuring by laser is a cold and flexible process, and does not heat or harm the glass substrate.

- Laser Structuring is made in a contact-free way => no risk of breakage

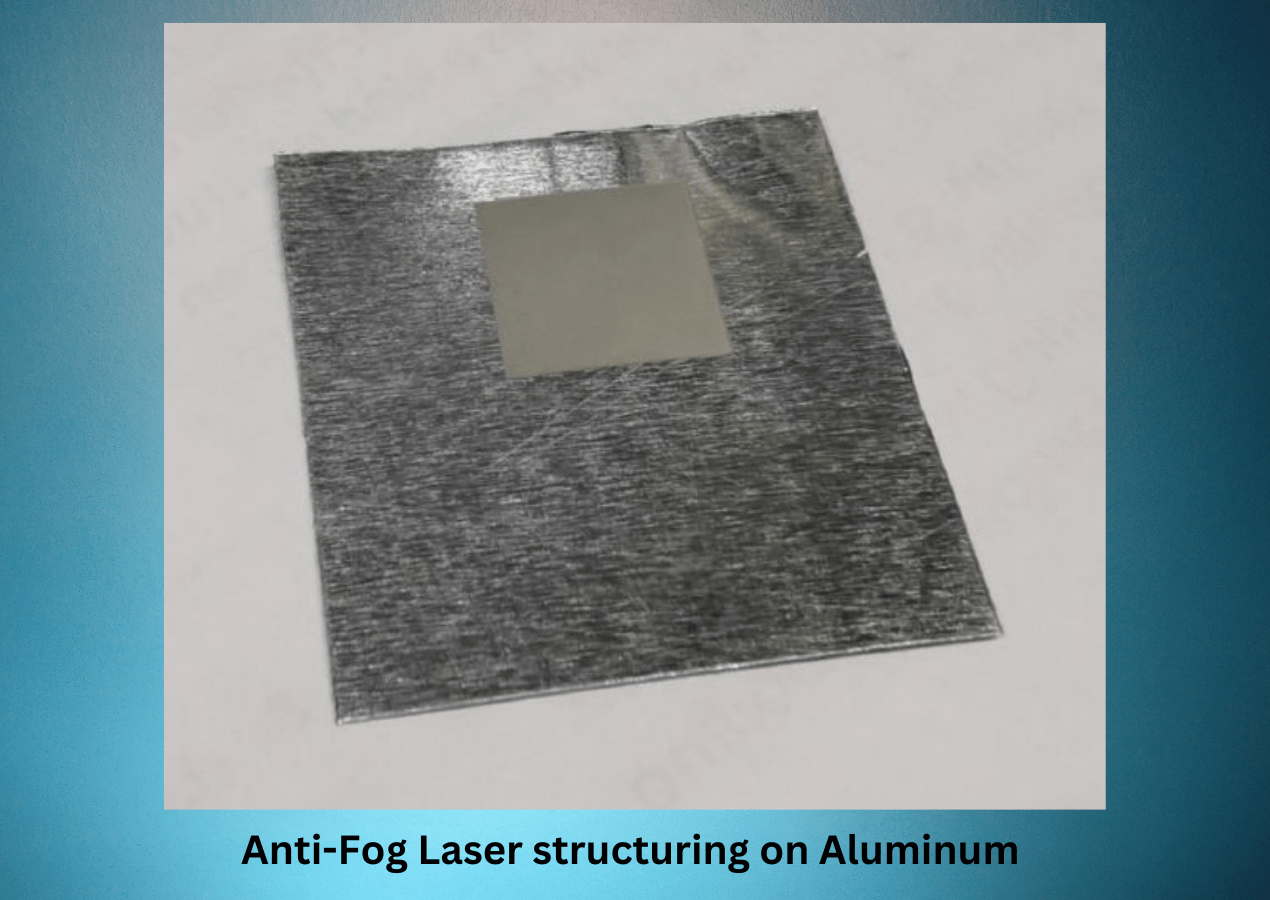

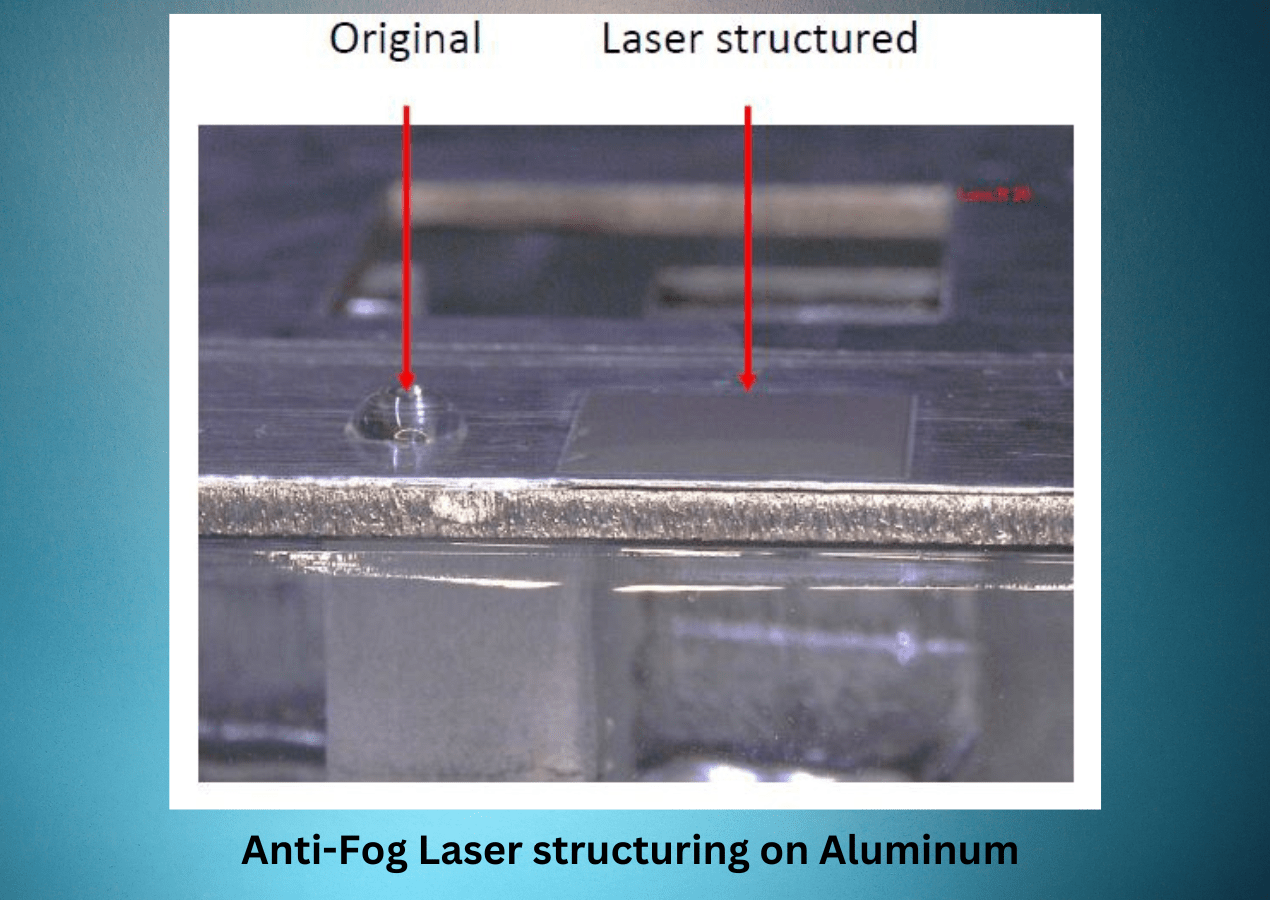

- Anti-Fog Laser Structuring can also be used on aluminum substrates, turning the surface into a water repellent, non condensing surface.

- The Anti-Fog Laser Structuring process is environmentally friendly (no chemicals, no waste products)..

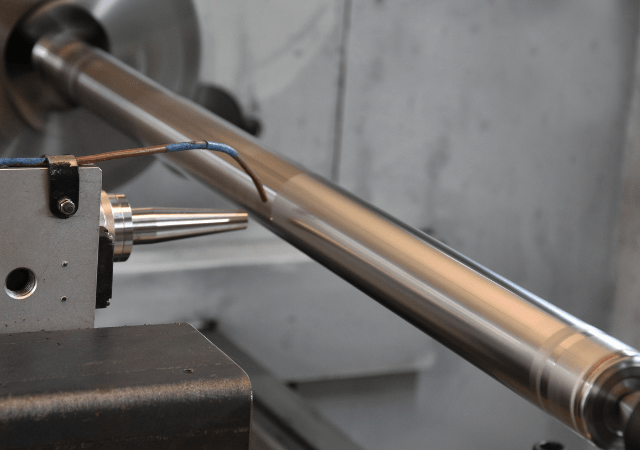

Laser Texturing

Rolling Mill Tempering Roll Surfaces

- The PRC Laser Roll Texturing Machine uses a pulsed fiber laser with patented optical laser disorder texturing technology.

- This technology allows the creation of textured sheet surfaces that are completely randomized and uniform over the full roll width.

- The CNC laser texturing machine accurately controls the laser process to produce highly consistent and repeatable surface finishes.

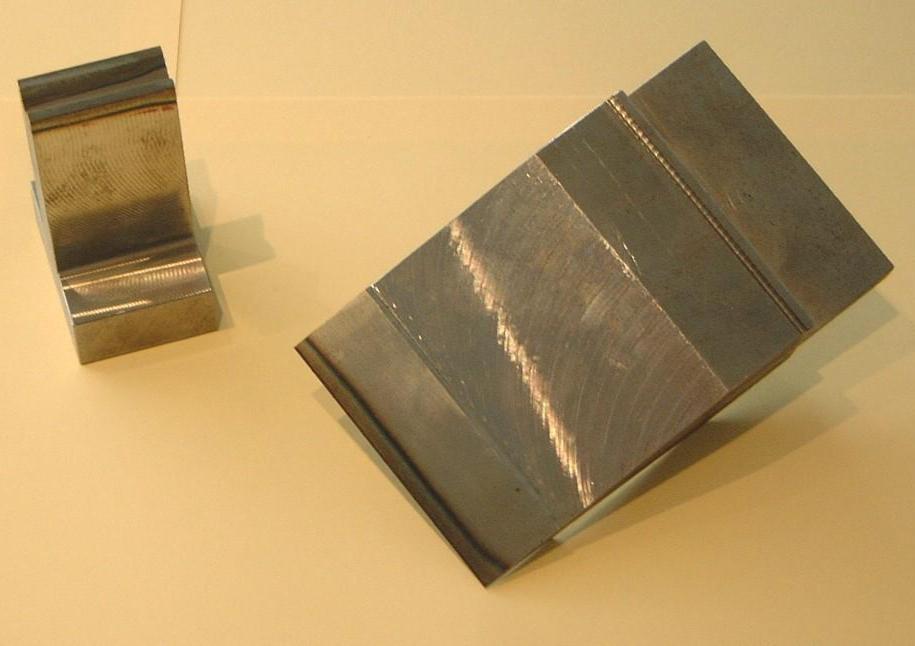

Laser Hardening - Heat Treatment

The Laser Hardening Process is a heat treatment process, used to improve strength and durability of component surfaces, such as Press brake tools, metal working tools, automotive components, axles, etc…

Perfect solution for highly stressed, complex components. Targeted heat input, confined to local area, no distortion.

The very precisely controlled non-contact laser process, opens up applications that would not be possible with conventional hardening methods (induction or flame).

Highly consistent and repeatable hardening strength. Offering significant benefits in tool making, etc…

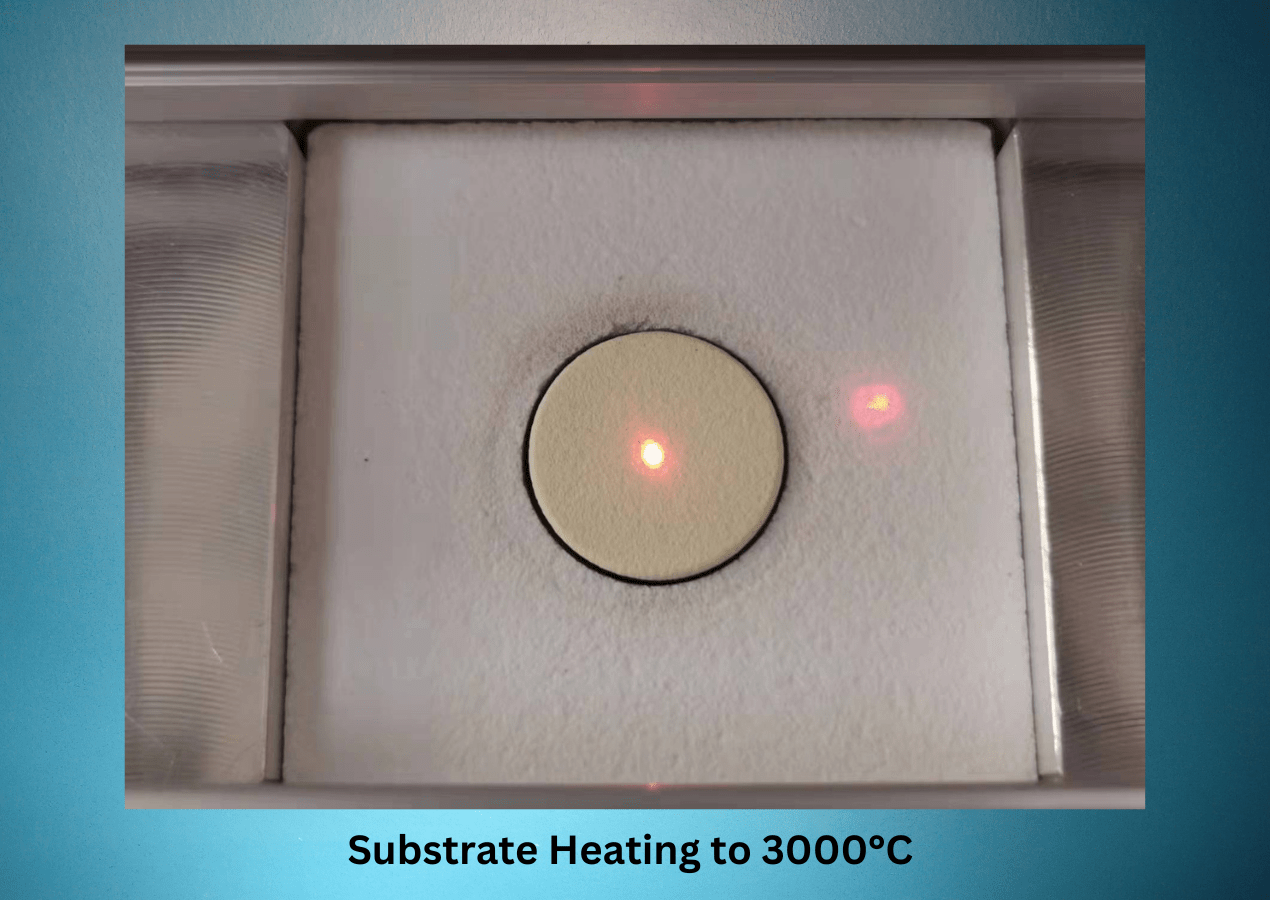

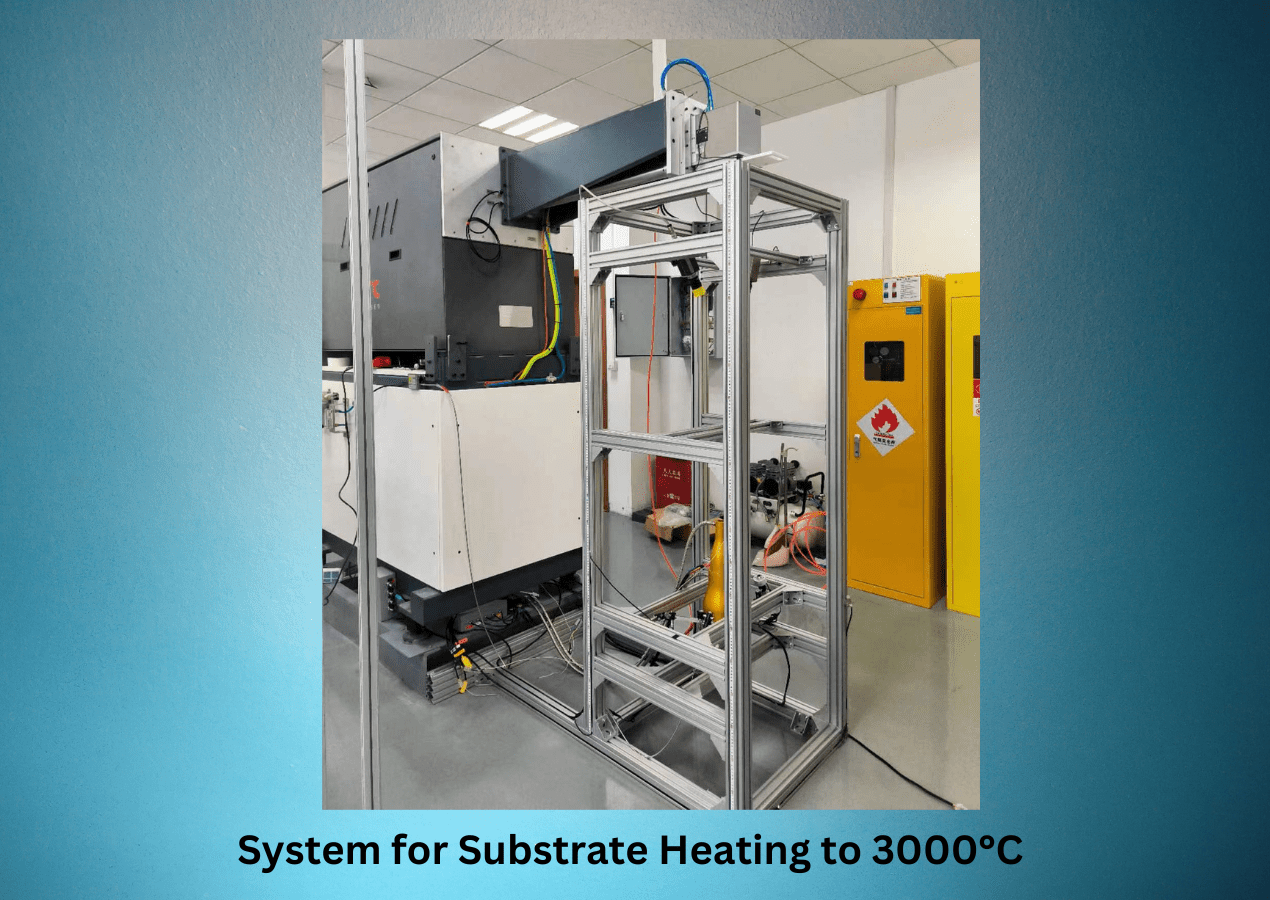

Substrate Laser Heating up to 3000°C

- Non-contact Laser Substrate Heating up to 3000°C

- Contact-free laser process => NO burned particles or whatsoever on surface!!

- This laser Heating Process can be used on most materials!!.

- Environmentally friendly process: no chemicals, no waste products.